Knowing how to effectively hand wrap a pallet is a useful skill that will help improve your performance in the warehouse.

Many warehouses have wrap machines that do the work for you. However, these machines don’t work sometimes and can take up too much of your time trying to set them up so that they can correctly wrap your pallet.

Use the steps outlined below to quickly and securely wrap a pallet.

Steps for Hand Wrapping a Pallet

1. Pull your shrink wrap about two to three feet.

2. Tuck the stretched bit between the load and the skid or between boxes.

3. While moving in a forward motion, overlap the stretch wrap at least an inch down the skid to hold the load firmly. Wrap the area between the bottom of the load and the skid at least three to five times so that it doesn’t slide off during transit.

4. As you make your way up the pallet, twist it at every turn (as shown in this video) to provide a stronger hold of the load.

5. Once you get to the top, wrap it around three to five times just like you did the bottom to hold the items at this level more tightly.

6. Make your way down to the bottom without twisting the roll this time.

7. When you get to the bottom, break the film with your hand and stick it to the pallet.

8. You may need to repeat steps 1 to 6 a few times for heavier and/or taller pallet loads.

Securing the Load to the Pallet

In addition to overlapping the skid and the bottom of the load with stretch wrap and going around it several times, you can use these methods to hold the pallet more tightly.

1. Use edge protectors – if your load contains angular items with straight edges such as cardboard boxes, you can use edge protectors to hold the items in place at the edges. First, tape the protectors onto the load then stretch wrap them.

2. Poly cord strapping – for fragile material such as glass bottles and cans of beer, poly cord strapping provides extra protection by preventing the items from moving around unless the cord is physically broken. Using poly cord strapping, wrap your pallet in multiple places such as the middle and the top of the pallet. The strapping should always be used on top of the stretch wrap.

How Much Stretch Wrap Do You Need?

The amount of stretch wrap you need will depend on the weight and height of the load.

Light items such as empty cardboard boxes, bubble wrap and pillows don’t need much wrap to held them down.

On the other hand, items like boxes of meat at the bottom tend to get smashed by items at the top. To reduce the risk of the load leaning too much and falling, you may need to use a lot more stretch wrap.

Tall loads also tend to have a higher center of gravity so using more wrap especially at the top will protect them from falling over.

Dos and Don’ts

- Wear gloves when hand wrapping to avoid friction burns on your hands. “Hand savers” are also a good option for this purpose.

- Put heavy loads at the bottom of the pallet to create a more stable base. Putting them at a higher height raises the center of gravity of the load thereby increasing the risk of it tipping over while in transit.

- Avoid dizziness by crouching instead of bending while hand wrapping a pallet.

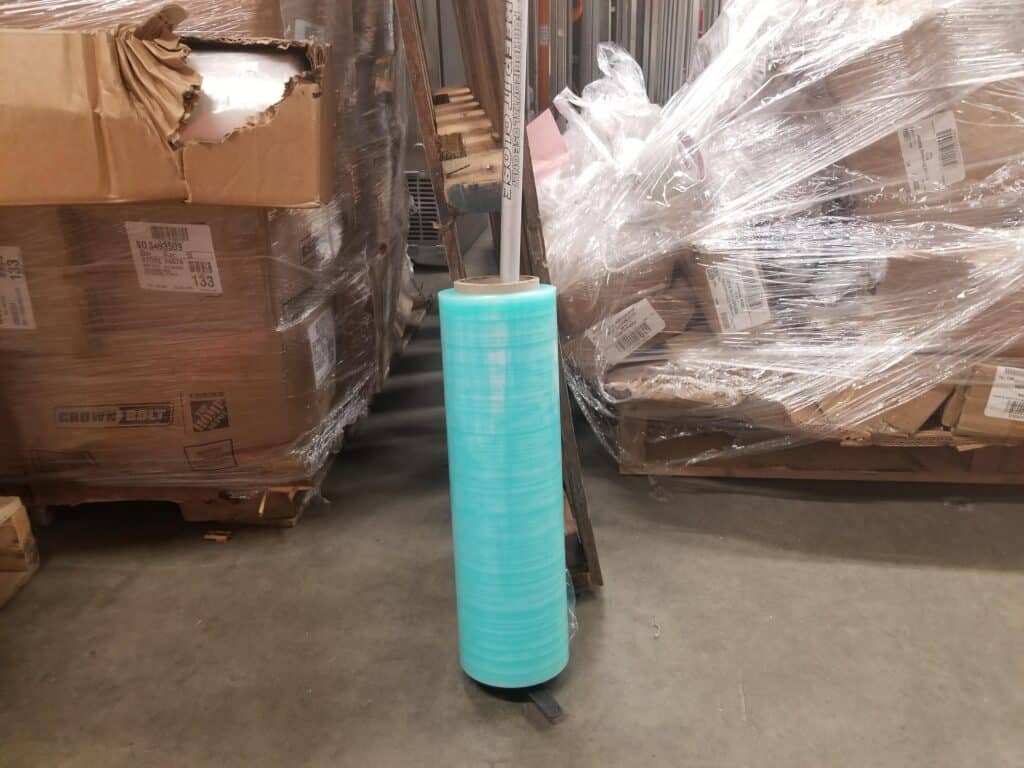

- Using a stretch wrap dispenser will make your work easier and also protect your hands from friction burns.

- Hold the stretch wrap roll with a picking stick or similar equipment so that you don’t have to bend while wrapping the bottom of the pallet. Bending while going around the pallet may causes dizziness and back pain.